This instruction show you guide on how to remove and install gearcase assembly for ISUZU 4JJ1 Euro 4 N series truck.More repair cases please refer to:ISUZU Trouble Repair.

Procedures:

Removal

1.Remove the engine assembly from the vehicle.

2.Remove the cylinder head.

3.Remove the generator bracket.

4.Remove the vacuum pump.

5.Remove the power steering pump.

Remove the power steering pump at the engine side with the hose attached.

Fasten the power steering pump with hose attached to any suitable position with a wire.

6.Remove the water pump.

7.Remove the fuel supply pump.

8.Remove the crank pulley.

9.Remove the gearcase cover.

10.Remove the idle gear A, idle gear A shaft, idle gear C, and idle gear C shaft.

11.Remove the oil pump.

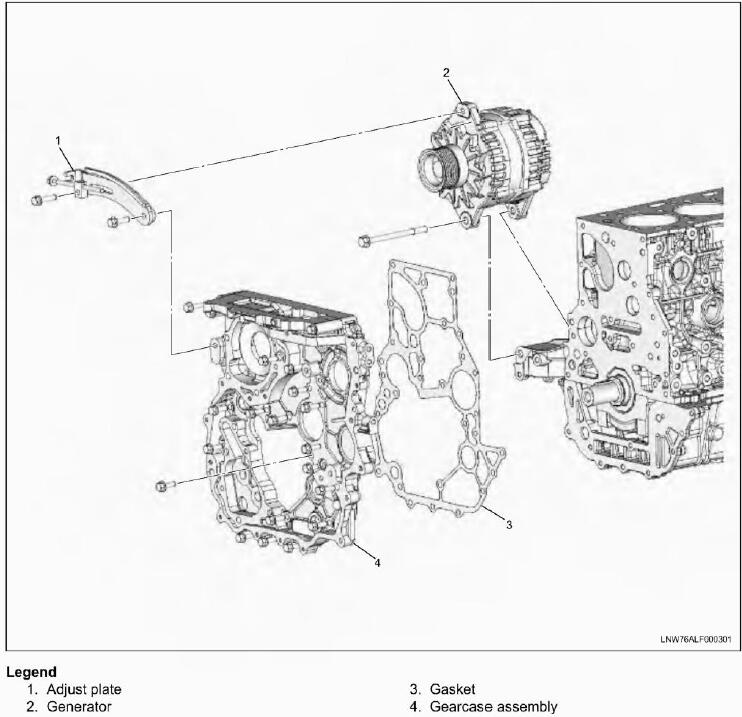

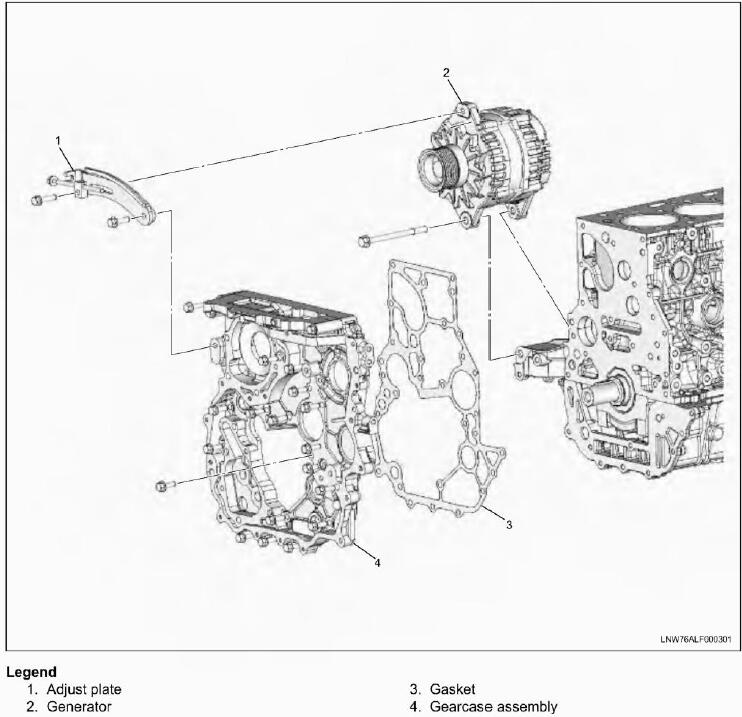

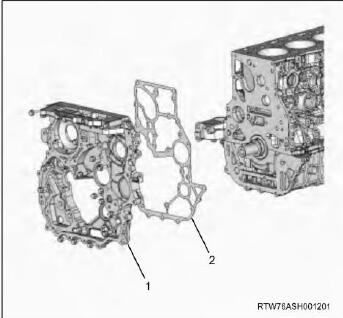

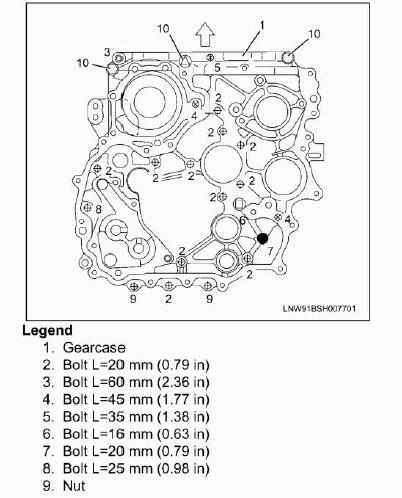

12.Remove the gearcase(1) and gasket(2).

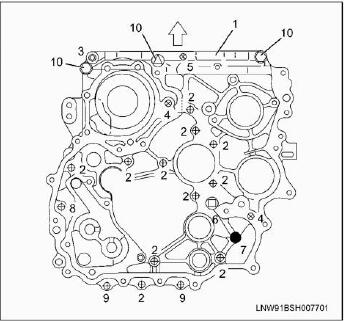

NOTE: Do not remove the bolt(10) when attaching/detaching the gearcase.

Installation

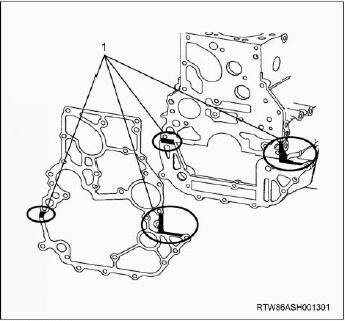

1.Install the gasket.

Apply liquid gasket(TB-1207B or equivalent) to the area indicated in the diagram(1).

The gasket applies it to the both sides

After applying the liquid gasket, install the gearcase within five minutes.

2.Install the gearcase.

Align the positions of the dowel pin and bolt and install the gearcase.

Do not remove the bolt(10) when attaching/detaching the gearcase.

3.Install the oil pump.

4.Install the idle gear A, idle gear A shaft, idle gear C, and idle gear C shaft.

5.Install the gearcase cover.

6.Install the crankshaft pulley.

Install the crankshaft pulley, washer and bolt and tighten them at the specified torque. At this time, apply engine oil to the bolt seat surface and threaded portion.

Tightening torque:185 N.m(18.9kg-m/137 lb-ft)

NOTE: Do not reuse the bolt and washer of the crankshat pulley.

7.Install the fuel supply pump.

8.Install the water pump.

9.Install the power steering pump and tighten it at the specified torque.

Tightening torque:25N-m(2.5kg-m/18 Ib-ft)

10.Install the vacuum pump.

11.Install the generator.

12.Install the cylinder head.

13.Install the engine assembly to the vehicle.

Leave a Reply